R12 Atmospheric corrosion

Aim: To show how atmospheric corrosion occurs and which redox half-reactions are responsible for it |

Corrosion has posed a

problem for centuries and is evident in the home, garden, transport vehicles (from

bicycles to cars), shipping, industry and underground piping. The consequences of

corrosion are all too familiar, parts have to be replaced, customers become dissatisfied

and there are other adverse financial consequences. 1/8th of the annual UK production of

steel is needed to replace iron lost through rusting.

Combating of corrosion often requires expensive surface treatment e.g. painting,

galvanisation, tinning etc., which often is associated with products which themselves

cause serious contamination of land, water and air.

Rusting of iron.

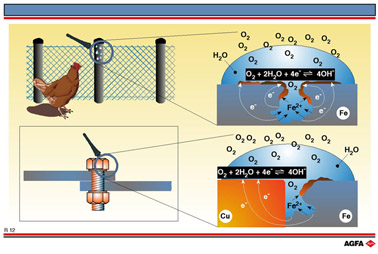

Corrosion is a widespread problem which can be explained in terms of redox reactions as

represented on illustration R12. The top right-hand side shows an iron surface which is in

contact with water containing a little dissolved oxygen.

All the necessary reagents are present to form a corrosion cell. (This is a simple

electrochemical cell in which corrosion occurs.) The etched out corrosion cell depicted

has an anodic area, a cathodic area, a suitable transport medium for electrons (the metal

itself) and an aqueous solution through which ions can move. The following electrochemical

half-reactions are important when considering how the anodic and cathodic areas are

formed:

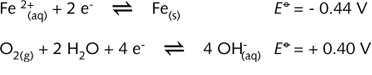

From

the above ![]() -values

it can be deduced that Fe, the metal surface, is the anode. The top of

the water droplet is in contact with the oxygen in the air and so the

concentration of oxygen is greater here than in the water droplet itself.

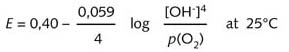

This region of higher concentration is the main cathodic zone. The Nernst

equation (R8) shows that the oxidising potential increases with an increase

in oxygen partial pressure.

-values

it can be deduced that Fe, the metal surface, is the anode. The top of

the water droplet is in contact with the oxygen in the air and so the

concentration of oxygen is greater here than in the water droplet itself.

This region of higher concentration is the main cathodic zone. The Nernst

equation (R8) shows that the oxidising potential increases with an increase

in oxygen partial pressure.

![]()

The iron(II) ions which are formed in the water come into contact with the rapidly diffusing hydroxide ions and react to form insoluble iron(II) hydroxide. This is in turn oxidised by the air to iron(III) oxide.

![]()

The

cathode or cathodic zone is more than just the iron metal. Iron together with the oxides

FeO, Fe2O3, and hydroxides Fe(OH)2 and Fe(OH)3

forms the complex cathodic surface which is called rust.

Constant diffusion takes place between the anodic and cathodic areas and, because the

cathode receives its oxygen supply from the air, this type of corrosion is called

atmospheric corrosion.

A few characteristics of the rusting process are:

• The presence of salt in the water leading to a greater

degree

of corrosion, because it is ionic and when

dissolved

in water its ions encourage the transport of

ions

already within the system.

• Corrosion

only continuing if the rust which is formed

conducts

electrons. For iron this is the case but if the iron

is incorporated into a steel alloy e.g. stainless

steel

( 18% Cr, and 8% Ni ) then an insulating layer

of

CrO2

forms on the surface of the iron and if a

rusting

process

starts it stops almost immediately due to

lack of

electron transport.

• Presence

of an acid results in H+ ions from the acid

reacting

with the hydroxide ions produced during

corrosion

to form water. This will result in the

formation

of more hydroxide ions and more corrosion.

Corrosion at the junction of copper and iron

When two metals, one of which is iron, are joined together it is important that corrosion

of the iron is prevented. At the bottom left-hand side of R12 a copper bolt has been used

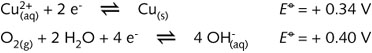

to join two iron plates. Copper metal has a much lower reducing power than iron. The redox

couples to be considered are:

The values of ![]() are very similar. In non-standard situations the order can even be reversed

and the oxidizing and reducing power lost. Copper corrodes very little

but is an excellent conductor of electrons. It therefore provides an excellent

cathodic surface in the presence of iron ,thus increasing the corrosion

of the iron. The copper bolt still exists after the two iron plates have

corroded away!

are very similar. In non-standard situations the order can even be reversed

and the oxidizing and reducing power lost. Copper corrodes very little

but is an excellent conductor of electrons. It therefore provides an excellent

cathodic surface in the presence of iron ,thus increasing the corrosion

of the iron. The copper bolt still exists after the two iron plates have

corroded away!