ST15

Separation of gas - gas mixtures

| Aim:

To isolate nitrogen gas from air using membrane separation. |

Gas - gas

mixtures can be separated either by fractional distillation of liquified

gas mixtures, e.g. liquid air, or by passing them over a series of membrane

separators. These membranes are built of bundles of hollow polymer tubes.

Gases can diffuse through their walls. The size of the pores in the polymer

walls determines which gas particles (molecules) pass through easily and

which with more difficulty.

For

most membrane types the permeability to oxygen gas is greater than that

to nitrogen gas, seeing the differences in molecular size. The ratio of

the number of oxygen to nitrogen molecules passing through the membrane

determines the selectivity of the membrane, and should be at least four.

This ratio is called the selectivity or separation factor of the membrane.

In practice this means that the gases must pass through several membranes

in order to obtain as complete as possible a separation. The table below

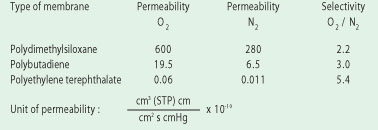

gives the selectivity of various polymer types for N2/O2

gas mixtures. The speed of separation can be increased by a combination

of increased pressure (from 0.7 MPa to 10 MPa) and increased temperature

(from room temperature to 95°C). The permeability of these membranes

is always higher for oxygen gas than for nitrogen gas: an oxygen-gas molecule

has a smaller volume (22.467 Å3 ) than a nitrogen-gas

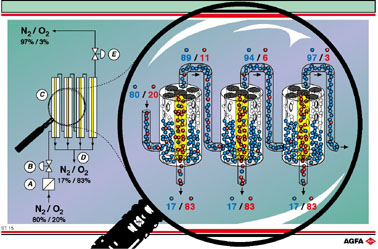

molecule (23.647 Å3 ). On the illustration, below left,

the incoming air mixture is compressed (A). The gas mixture is then let

in, through a regulator (B), to the membrane separator (C). At the bottom

of the separator (D) oxygen enriched air is discharged. At

the top of the separator almost pure nitrogen is discharged via a regulator

(E).